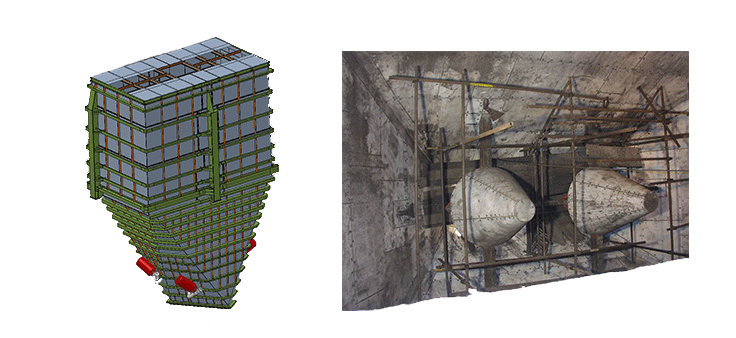

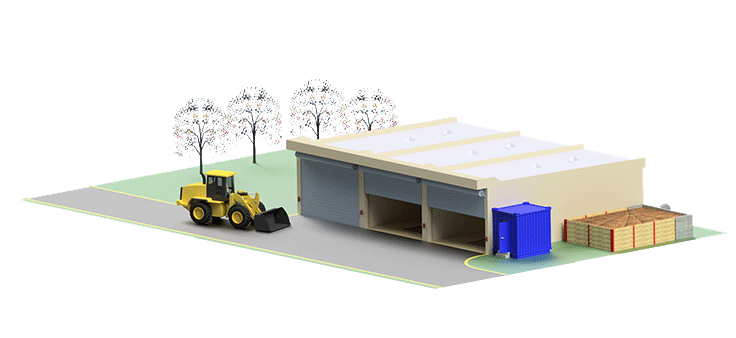

The division focuses on transport and handling of materials for power plants, heating plants, coke plants, paper mills and others. For these plants we design landfills, storage facilities, sorting and crushing plants. The division focuses on transport and handling of materials for power plants, heating plants, coke plants, paper mills and others. For these plants we design landfills, storage facilities, sorting and crushing plants. We address material flow disturbances on the transport route and in storage tanks using active and passive elements. We offer problems solutions to the transition of coal plants to alternative fuels such as waste, biomass, solid alternative fuels (SAF), etc.

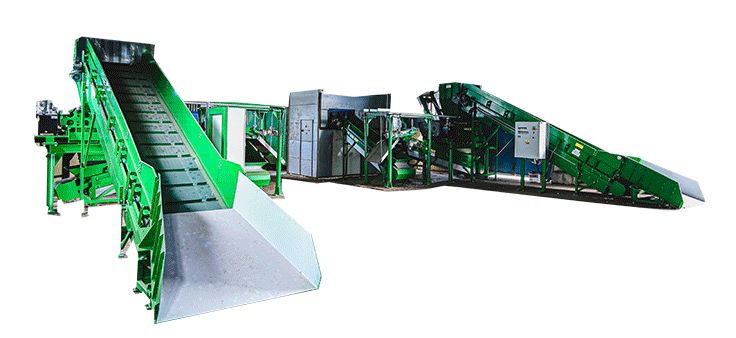

Within the Environment division, we handle environmental projects for our customers, such as composting plants and biodegradable waste treatment lines, EWA aerobic fermenters and BEWA boxes. Within the Environment division, we handle environmental projects for our customers, such as composting plants and biodegradable waste treatment lines, EWA aerobic fermenters and BEWA boxes. We design and supply our own fuels production lines using industrial waste to make the final product known as ENERGIT (crushed mixtures for energy recovery). Moreover, we offer the design and implementation of technologies to process old environmental loads. To eliminate dust, we apply area spraying and local scraping of open landfills. Water mist based applications can be used to reduce dust during rail car unloading. We design and implement lines to transport sludge from wastewater treatment plants for further energy recovery.

The Mineral Processing division focuses on mineral processing technologies. In particular, coal and lignite, graphite, pyrope sands, shale, gold, iron ore, magnesite and other raw materials. The Mineral Processing division focuses on mineral processing technologies. In particular, coal and lignite, graphite, pyrope sands, shale, gold, iron ore, magnesite and other raw materials. The technologies are always designed with an emphasis on the raw material to be extracted and the mining location. Customer requirements, geological surveys, laboratory analyses and tests form the basis for proper design. Within the scope of the designed technologies, we supply crushing and screening plants, treatment of the raw material in heavy liquids, treatment in hydrocyclones, flotation, filtration, stockpiles, storage facilities and expediting.

EWA Fermenter Datasheet

EU ETV Certificate

EC/EU Declaration of Conformity

Belt Conveyor Product Datasheet

Redler Conveyor Product Datasheet

Passive Elements Product Datasheet

Sword nozzle Product Datasheet

Air Cannon Product Datasheet